How i3dfigure Uses 3D Printer Materials for Polymer Clay Figurines

Share

How i3dfigure Uses 3D Printer Materials for Polymer Clay Figurines

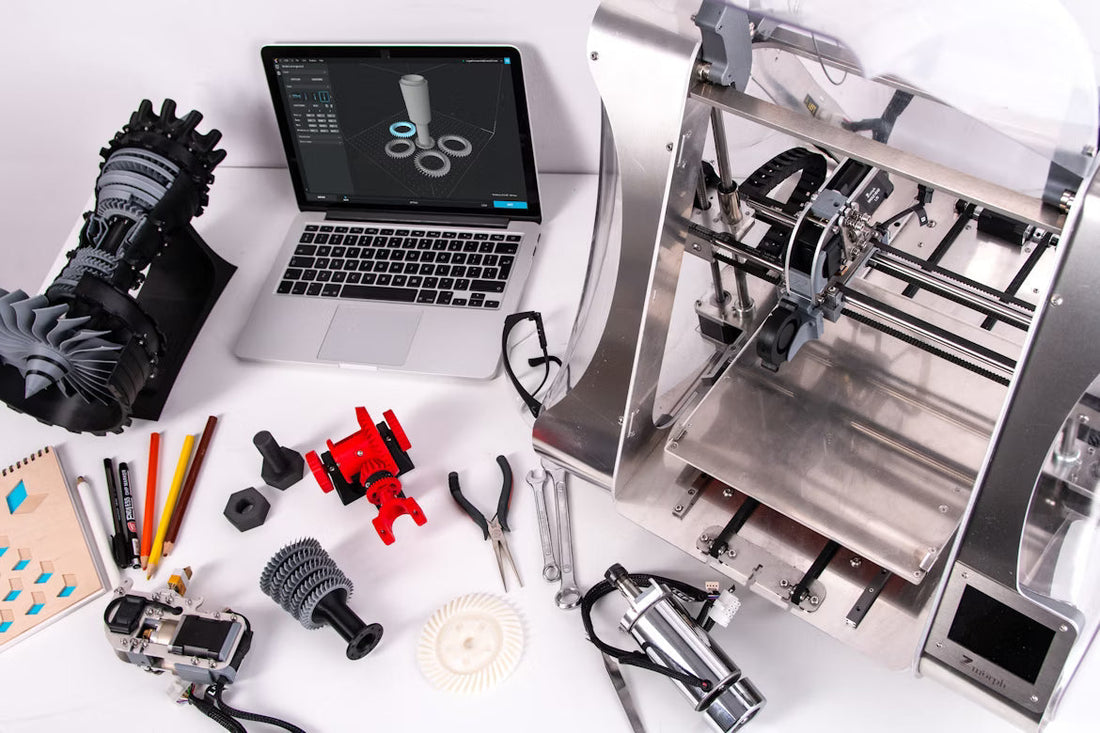

3D printer materials can seem confusing at first, but they are the key to turning digital ideas into physical creations. At i3dfigure, these materials are used to craft intricate polymer clay figurines quickly and precisely. Let’s dive into how it all works.

What Are 3D Printer Materials?

Definition and Basic Concept

3D printer materials are substances used to build objects layer by layer in a 3D printer. Think of it like “digital sculpting meets physical reality.”

Common Types of 3D Printer Materials

Common options include PLA, ABS, resin, and flexible filaments. Each has unique properties—some are rigid, some bend, and some capture fine details.

Why Material Choice Matters for Figurines

Choosing the right material ensures durability, surface finish, and precision. For figurines, fine detail is crucial, so resins are often the go-to choice.

Overview of Polymer Clay in Figurines

What Is Polymer Clay

Polymer clay is a pliable modeling material that hardens when baked. It’s perfect for small sculptures and detailed features.

Why i3dfigure Chooses Polymer Clay

i3dfigure loves polymer clay because it captures intricate details and allows vibrant colors. Combined with 3D printed molds, it makes lifelike figurines possible.

Advantages for Small-Scale Figurines

Polymer clay is inexpensive, easy to handle, and ideal for limited-run productions. You can experiment freely without wasting expensive materials.

SLA 3D Printing in Tooling

How SLA Printers Work

SLA (Stereolithography) printers use a laser to cure liquid resin layer by layer, creating extremely detailed objects with smooth surfaces.

Using 3D Printed Molds for Polymer Clay

i3dfigure prints molds and tooling with SLA printers. These molds guide the polymer clay into the desired shapes, capturing tiny features like facial expressions or costume folds.

Benefits Over Traditional Tooling

Traditional metal molds are expensive and time-consuming. 3D printed molds are faster, cheaper, and perfect for small batches or prototypes.

Step-by-Step Workflow at i3dfigure

From Digital Sketch to 3D Model

It all starts with a digital sketch. Artists design figurines on 3D software, refining every detail before printing.

Printing the Tooling

Next, SLA printers turn the digital model into physical molds or jigs. The accuracy ensures that each clay figurine is consistent.

Shaping the Polymer Clay Figurine

Finally, polymer clay is pressed or shaped using the 3D printed tooling. After baking, the figurine is ready for painting and finishing touches.

Advantages of Using 3D Printer Materials

Faster Prototyping and Iteration

Designs can be tested and refined quickly, reducing mistakes and speeding up production.

High Detail and Precision

SLA printing captures fine features, making figurines more lifelike and polished.

Customization and Creativity

Artists can experiment with shapes, textures, and designs without being limited by traditional molds.

Common Challenges and Tips

Material Limitations and Durability

3D printed molds can wear out if used too many times. For long-term production, they may need reinforcement or replacement.

Post-Processing Needs

Printed tools may require cleaning, curing, or sanding to perform perfectly.

Beginner Tips for Working with 3D Printer Materials

Start small, test your molds, and choose resins suitable for high-detail figurines. Observing i3dfigure’s workflow can help you avoid common mistakes.

Future Trends for i3dfigure and 3D Printing

Multi-Material Printing Possibilities

Future printers may combine rigid and flexible materials in one print, opening up new design options.

Integration with Digital Sculpting Tools

Combining 3D modeling software with printing makes the process smoother and faster for artists.

Expanding Small-Batch Figurine Production

3D printing allows i3dfigure to create limited editions efficiently, keeping costs low and creativity high.

Conclusion

3D printer materials make creating detailed polymer clay figurines accessible and flexible. With SLA tooling, i3dfigure turns digital sketches into lifelike sculptures efficiently. For beginners and artists alike, this combination of technology and craftsmanship opens a world of creative possibilities.